India’s industrial expansion in power, pharmaceuticals, chemicals, oil & gas, and manufacturing has increased the demand for high-precision pipeline system design and installation. Modern plants require safe, efficient, and regulation-compliant piping networks that can handle high pressure, extreme temperatures, and sensitive process media.

Professional industrial piping contractors now offer turnkey industrial piping solutions that cover engineering, fabrication, installation, testing, and commissioning under one integrated scope. This approach reduces project risk, shortens timelines, and ensures consistent quality across all stages.

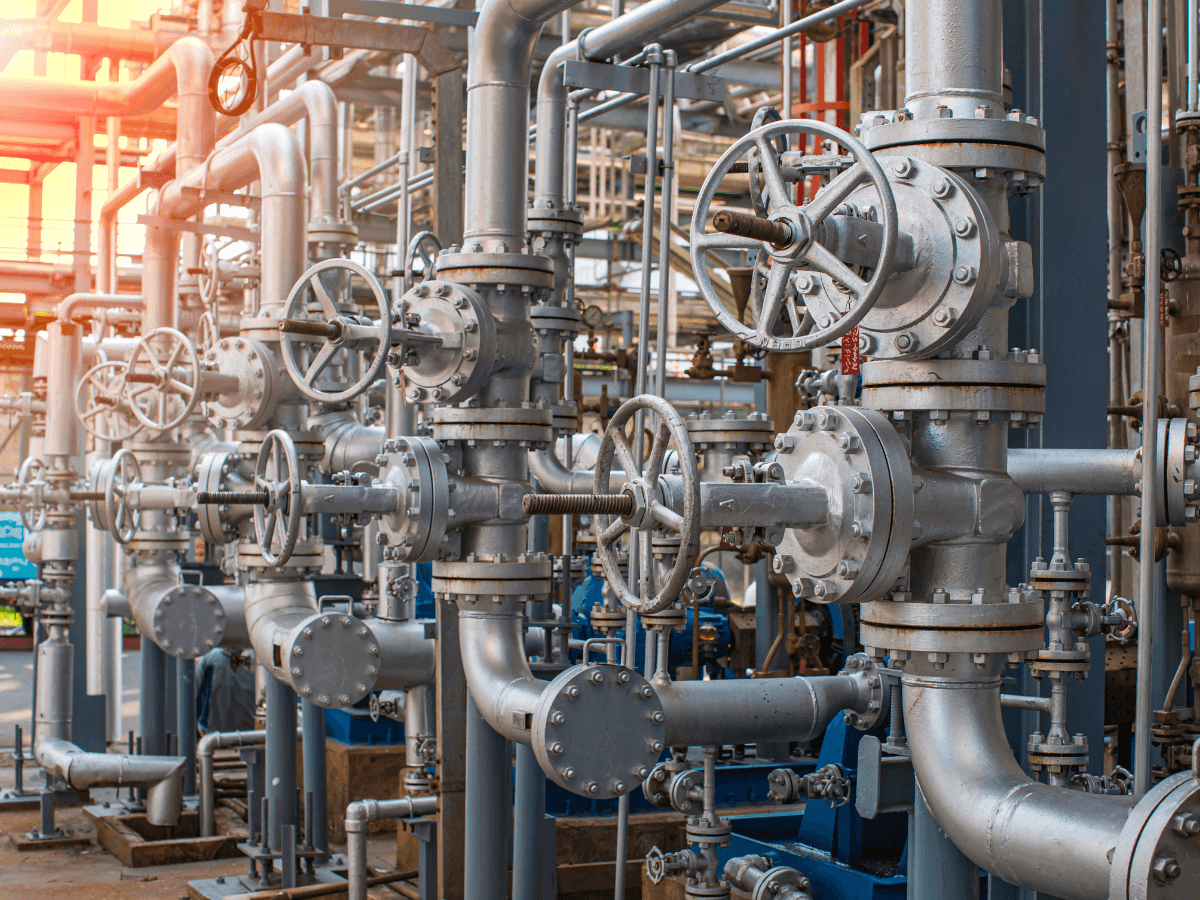

From stainless steel piping installation for clean processes to carbon steel pipeline installation for heavy-duty applications, turnkey execution ensures compatibility, durability, and operational safety.

With advanced technologies such as orbital welding piping solutions and modular piping systems, industries can achieve faster commissioning and lower lifecycle costs.

Advanced Pipeline System Design for Process Efficiency

Accurate pipeline system design is the backbone of every successful industrial project. Engineering piping contractors analyze flow rates, pressure drops, temperature loads, corrosion factors, and safety requirements before finalizing layouts.

For nitrogen vacuum inert gas piping solutions, leak-free design and material compatibility are critical to maintain controlled atmospheres in chemical and electronics manufacturing. Similarly, pharmaceutical piping solutions demand hygienic routing, dead-leg-free layouts, and easy cleanability.

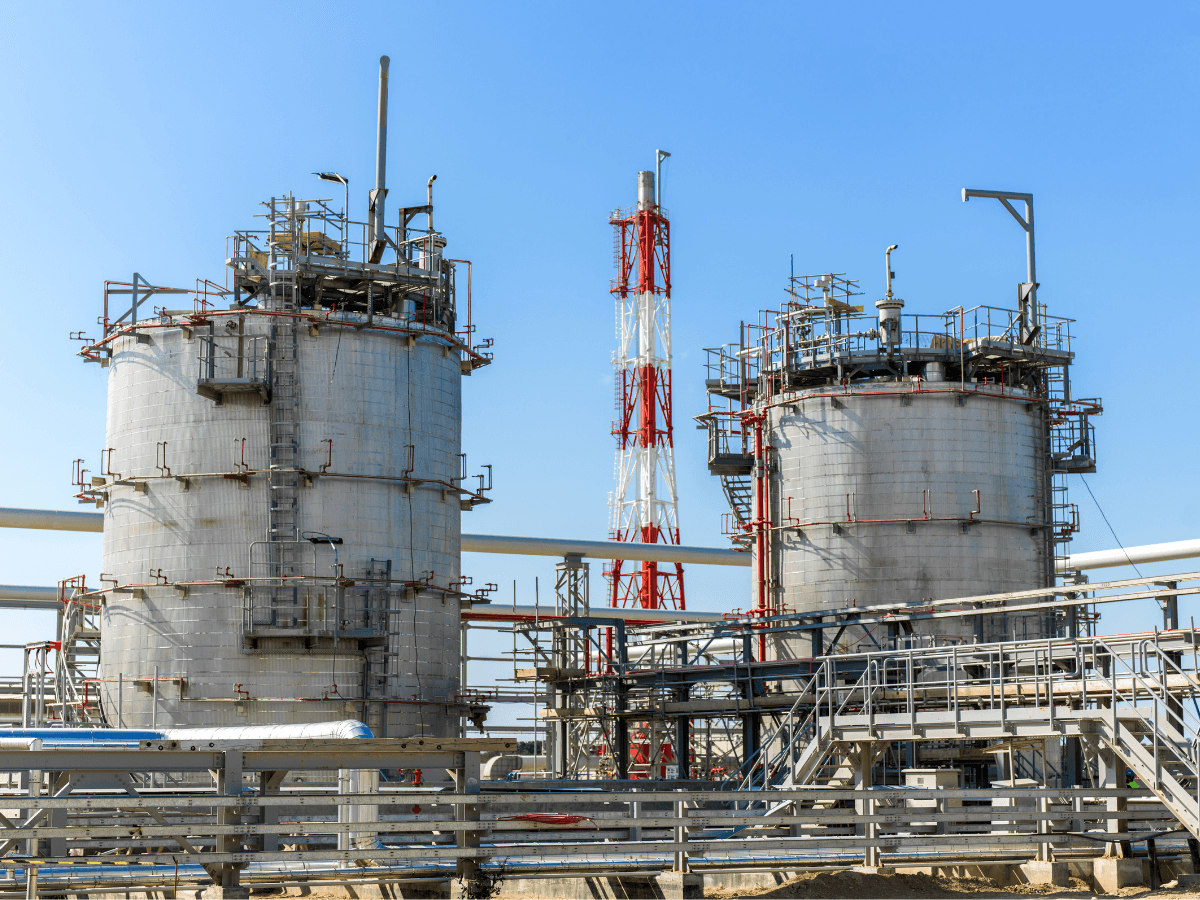

Fire prevention piping solutions are engineered with precise hydraulic calculations to ensure rapid response and full coverage during emergencies. IBR boiler piping solutions require strict compliance with pressure codes, expansion loop design, and stress analysis.

Piping project consultants use 3D modeling and simulation tools to optimize routing, reduce clashes, and simplify maintenance access.

Turnkey Piping Fabrication and Installation Services

A turnkey piping contracting company manages procurement, shop fabrication, site erection, and quality testing through a single coordinated team. This eliminates delays caused by multi-vendor dependencies and ensures full accountability.

Stainless steel piping installation is widely used in pharma, food, beverage, and specialty chemical industries due to its corrosion resistance and clean surface finish. Carbon steel pipeline installation is essential for steam, compressed air, oil, and cooling water systems where strength and cost efficiency are required.

Orbital welding piping solutions deliver uniform weld quality, especially for high-purity and high-pressure lines. Automated welding improves repeatability, reduces rework, and ensures compliance with stringent inspection standards.

Modular piping systems allow pre-assembled sections to be fabricated off-site, reducing on-site work, improving safety, and accelerating project completion.

Specialized Industrial Piping Applications

Different industries demand customized solutions based on their operating conditions and regulatory frameworks. Pharmaceutical piping solutions must meet GMP standards, with smooth internal finishes, clean welds, and contamination-free commissioning.

Nitrogen vacuum inert gas piping solutions support inerting, purging, and blanketing operations in chemical, semiconductor, and food packaging facilities. These systems require precise pressure control, high-integrity joints, and continuous monitoring.

Fire prevention piping solutions include sprinkler networks, hydrant systems, foam lines, and deluge systems designed to protect people, equipment, and infrastructure.

IBR boiler piping solutions serve thermal power plants, process industries, and large utilities, carrying high-pressure steam and feed water under extreme temperatures. Compliance with Indian Boiler Regulations ensures safety, traceability, and long service life.

After-Sales Piping Maintenance and Lifecycle Support

Reliable performance does not end at commissioning. After-sales piping maintenance plays a vital role in preventing leaks, corrosion, vibration damage, and pressure losses.

Engineering piping contractors provide periodic inspection, hydrotesting, NDT, valve servicing, and system optimization. Piping project consultants also support plant expansions, debottlenecking, and retrofitting of aging pipeline networks.

Turnkey industrial piping solutions with long-term service support help industries maintain uptime, reduce unplanned shutdowns, and extend the operational life of their assets.

Benefits of Choosing a Turnkey Industrial Piping Partner

A single turnkey partner manages design, procurement, fabrication, installation, and commissioning, ensuring seamless coordination and consistent quality standards. This integrated approach minimizes technical risks, improves schedule control, and delivers cost predictability.

With expertise in modular piping systems, orbital welding, fire safety networks, and high-pressure steam lines, a professional industrial piping contractor becomes a strategic partner for long-term plant reliability and growth.

FAQs – Turnkey Industrial Piping Solutions

Q1. What industries require turnkey industrial piping solutions?

Power, pharmaceuticals, chemicals, oil & gas, food processing, steel, and manufacturing plants rely on turnkey piping for safety and efficiency.

Q2. Why are modular piping systems preferred in modern projects?

They reduce on-site installation time, improve quality control, and minimize operational disruption.

Q3. What is the importance of IBR boiler piping solutions?

They ensure safe transport of high-pressure steam and compliance with statutory regulations.

Q4. How does orbital welding improve pipeline reliability?

It provides consistent, defect-free welds suitable for high-purity and high-pressure applications.

Q5. Do industrial piping contractors offer maintenance services?

Yes, most turnkey contractors provide after-sales piping maintenance, inspections, and system upgrades.

Leave a comment