Aluminium piping systems represent a major advancement in industrial utility distribution, particularly for compressed air and gas applications. Their engineered design aligns perfectly with modern manufacturing goals of efficiency, flexibility, and sustainability.

Superior Flow Characteristics & Energy Optimization

Aluminium pipes feature an exceptionally smooth internal surface that supports laminar flow. This minimizes turbulence, allowing utilities—especially compressed air—to travel efficiently across long distances while maintaining stable pressure levels. As a result, compressors operate under optimized conditions, enhancing overall system performance.

Corrosion Resistance for Clean & Reliable Operation

Aluminium naturally forms a protective oxide layer that resists corrosion. This ensures clean air and fluid delivery, protecting downstream equipment, tools, and processes from contamination.

Lightweight Construction with High Structural Integrity

Despite being lightweight, aluminium offers excellent mechanical strength. Its reduced weight simplifies handling and installation while minimizing stress on supporting structures—an important factor in retrofit and brownfield projects.

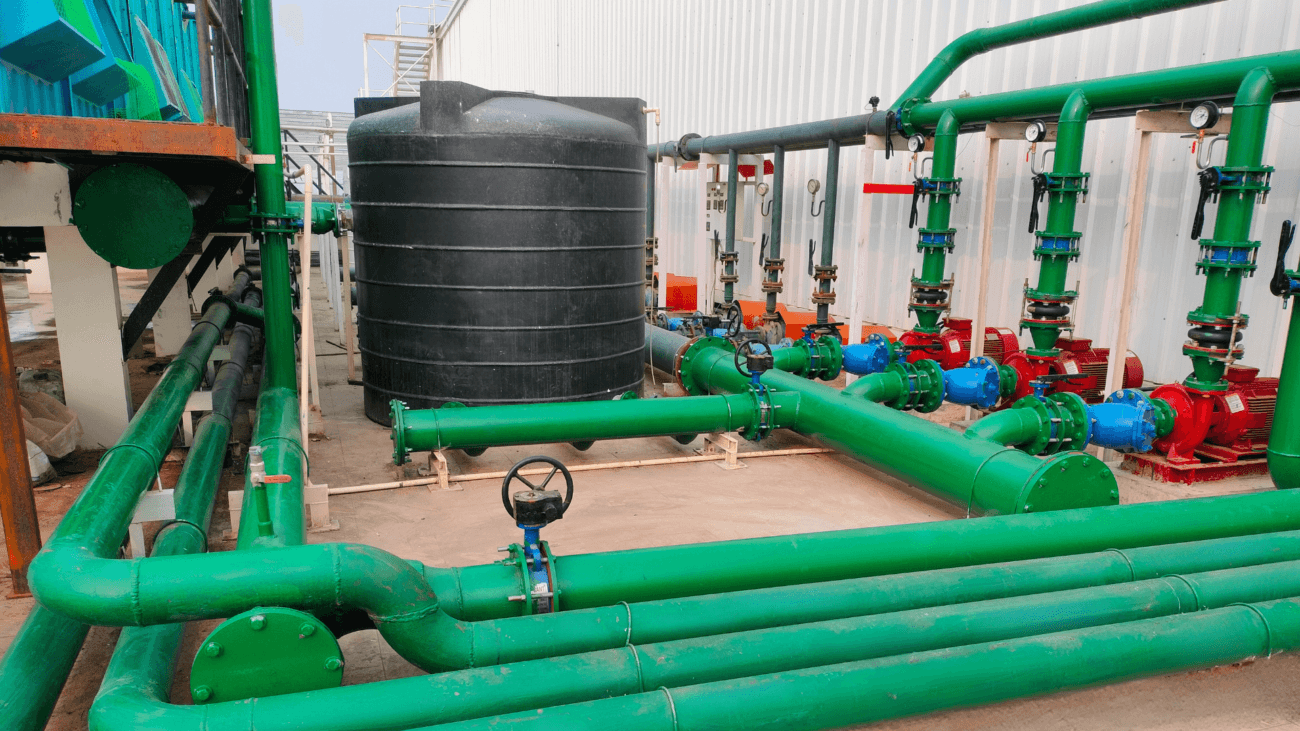

Modular Design for Scalability & Flexibility

One of the most significant advantages of aluminium piping systems is their modular nature. Facilities can easily expand, re-route, or modify utility lines as production needs evolve—without complex shutdowns.

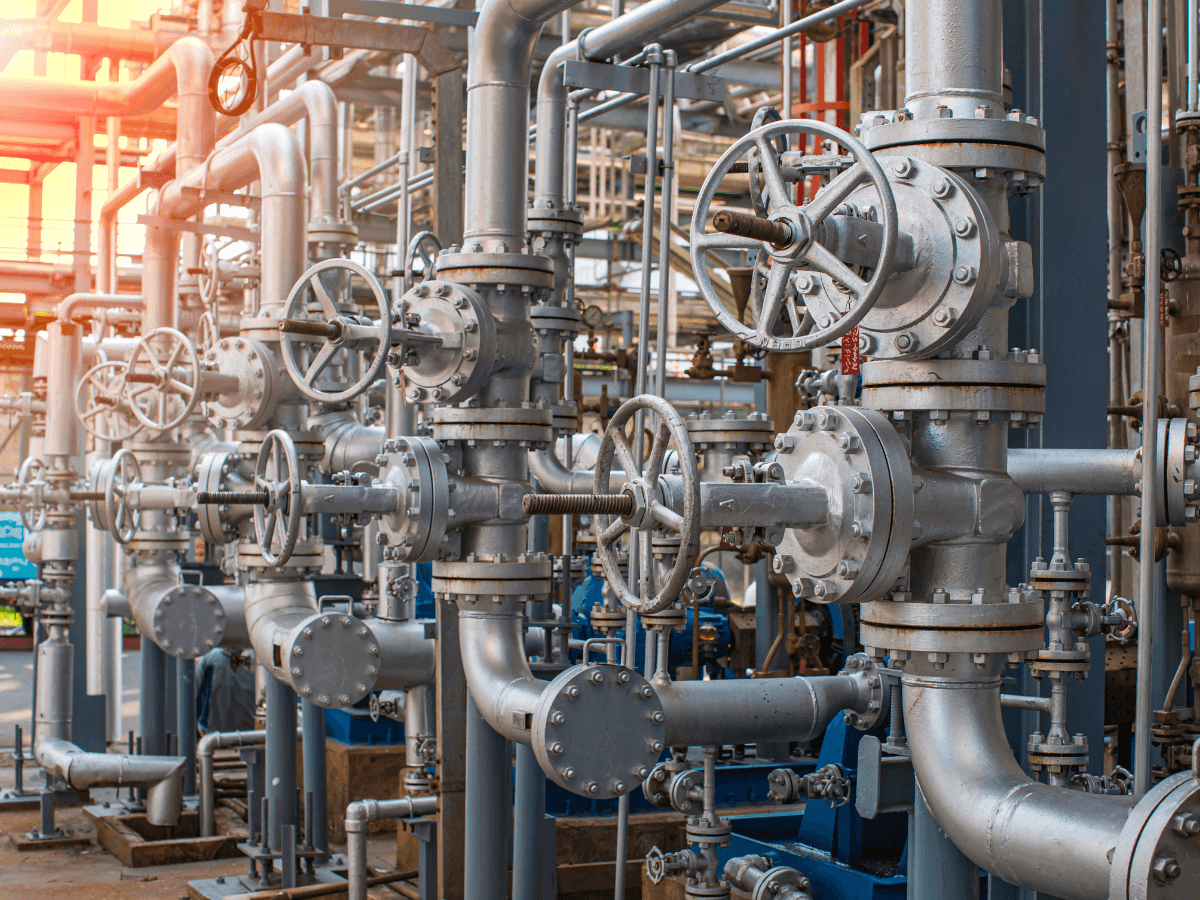

Precision-Engineered, Leak-Proof Connections

Advanced fittings ensure secure, airtight connections that maintain system integrity. These precision joints deliver consistent performance over extended operational lifecycles.

Typical Applications

- Compressed air distribution systems

- Vacuum and inert gas networks

- Automotive, FMCG, electronics, and pharmaceutical facilities

Turnkey Excellence: The Luthra Projects Advantage

At Luthra Projects, piping systems are engineered as complete solutions—not isolated components.

Our Core Strengths

- End-to-end turnkey execution

- Advanced 3D design & engineering

- Optimized layouts for energy efficiency

- Planned installation to minimize downtime

- Nationwide and international project capability

With a legacy of 50+ years and 6,500+ completed projects, we partner with industries to deliver utility piping systems that support productivity, reliability, and long-term value.

Leave a comment