In today’s hyper-competitive automotive manufacturing industry, companies are under constant pressure to improve efficiency, reduce downtime, and save costs. While most manufacturers focus on machinery upgrades and automation, there’s one “silent” factor draining profitability compressed air systems, often referred to as the “fourth utility” after electricity, gas, and water.

According to studies by the U.S. Department of Energy, compressed air systems can consume up to 30% of a plant’s total energy bill. For a leading automotive parts manufacturer in India, this hidden cost was eating into profits, making operational efficiency a top priority.

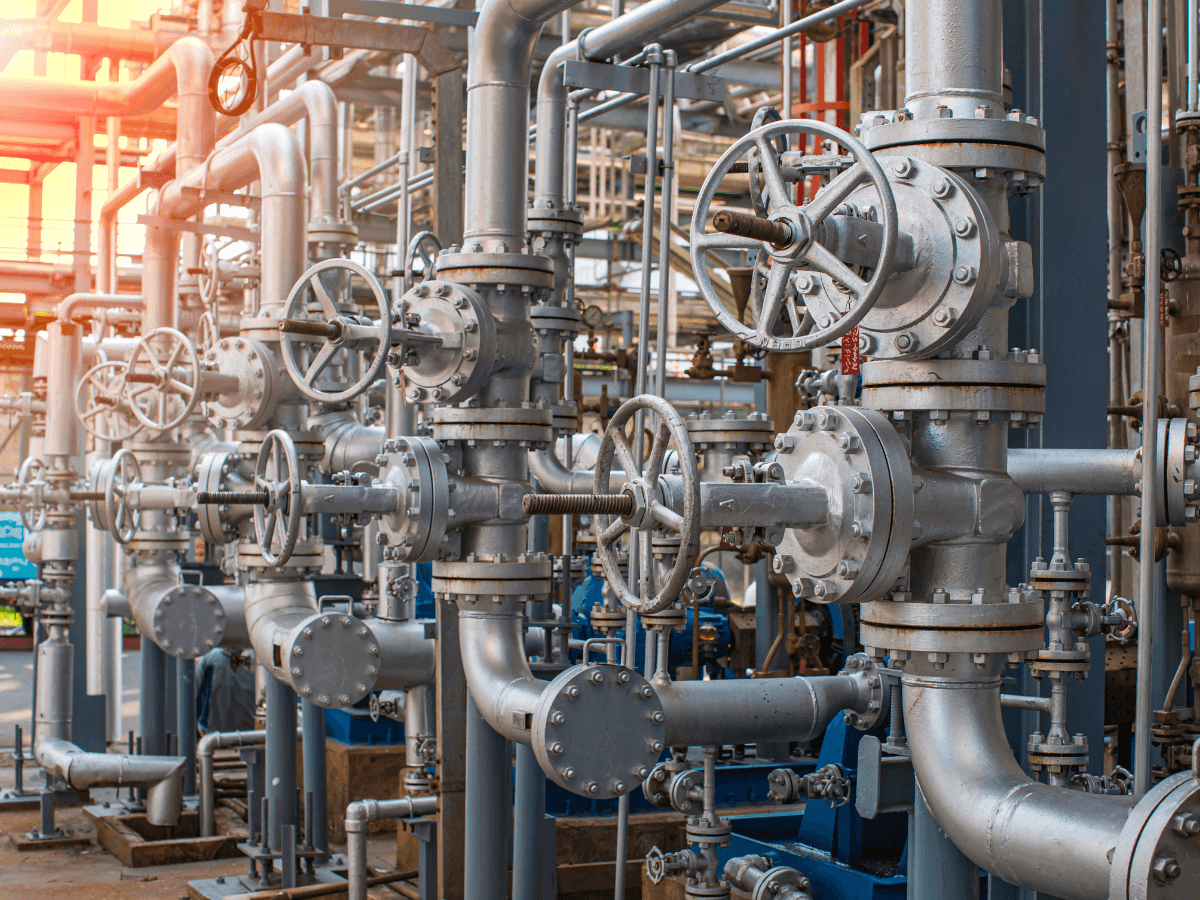

That’s where Luthra Projects, one of the best industrial piping companies in India, stepped in. With expertise in compressed air piping for the automobile industry, we helped the client transition from a leaky, inefficient system to a state-of-the-art compressed air network, achieving measurable results within months.

The Challenge: Rising Costs and Inefficient Systems

When we conducted an initial survey, the facility’s compressed air network was not only outdated but actively hurting productivity.

Skyrocketing Energy Bills

- – Two large rotary screw compressors were running full-time just to maintain air pressure in a leak-riddled piping system, driving electricity costs up.

- Inconsistent Air Pressure – Frequent pressure drops on assembly lines affected torque wrenches and pneumatic tools, risking quality control failures.

- Frequent Maintenance & Downtime – Corroded galvanized steel pipes required constant maintenance, causing unscheduled shutdowns.

It was clear that the root cause was a poorly designed piping network that needed a complete redesign.

3 Warning Signs Your Compressed Air System Is Inefficient

- Audible Hissing Noises – Even a single 1/8” (3 mm) leak can waste over ₹2,00,000 annually in energy.

- Compressors That Never Stop – If your compressors are always running, they are compensating for leaks rather than powering your production.

- Pressure Drops at Tools – If pneumatic tools or equipment perform poorly, your piping network design may be the problem.

The Luthra Projects Solution: Engineering Meets Efficiency

At Luthra Projects, our reputation as one of the best compressed air piping contractors in India comes from a data-driven approach. We don’t just replace pipes; we engineer complete solutions.

Step 1: On-Site System Audit

Our team conducted a comprehensive audit using ultrasonic leak detectors and inline flow meters. Findings included:

25%+ air loss from leaks.

Corrosion, poor routing, and undersized piping causing inefficiencies.

Step 2: Redesigning the Network

We replaced the outdated steel network with a 3D-modeled aluminium piping system:

Corrosion-Free – Clean, contamination-free air.

Laminar Flow Design – Smooth internal surfaces to minimize pressure loss.

Leak-Proof Fittings – Push-to-connect fittings for a reliable, future-proof system.

Step 3: Seamless Installation

We planned installation over a weekend shutdown, ensuring zero production delays. Post-installation testing confirmed balanced pressure levels and efficiency.

The Results: Measurable Impact

- 28% Energy Savings – Optimized compressors now consume less power.

- Consistent Air Pressure – Boosting productivity and product quality.

- Zero Emergency Maintenance – Leak-free system reduced unplanned downtime.

- 18-Month ROI – The project will pay for itself in under 2 years.

Why Choose Luthra Projects?

As one of the leading compressed air piping contractors in India, Luthra Projects has decades of expertise in industrial utility piping systems. We specialize in delivering turnkey compressed air piping for the automobile industry, offering:

- Tailored System Designs for efficiency.

- High-Performance Piping Materials for longevity.

- Nationwide Service & Support for automotive, pharmaceutical, FMCG, and heavy industries.

Contact Us

Luthra Projects recognized as one of the best industrial piping companies in India and let’s engineer a cost-saving compressed air system that delivers long-term ROI and reliability.

Visit Luthra Projects to book your on-site audit today.

FAQs – Compressed Air System

Why is compressed air called the “fourth utility” in manufacturing?

Compressed air powers tools, automation systems, and assembly lines, making it as critical as electricity, water, and gas.

How much can leaks cost my plant?

A single 1/8” (3 mm) leak can waste over ₹2,00,000 annually in electricity. Multiple leaks can easily cost crores over time.

Why switch to aluminium piping?

Aluminium is corrosion-resistant, lightweight, and provides laminar airflow, reducing energy consumption and extending system life.

How often should a compressed air system be audited?

We recommend an annual audit to identify inefficiencies before they escalate into major costs.

What ROI can I expect from a piping system upgrade?

Most facilities see a 12–18-month ROI through energy savings, reduced downtime, and lower maintenance costs.

Leave a comment