Industrial growth in India is driving strong demand for reliable, safe, and high-performance pipeline infrastructure. From pharmaceutical manufacturing to power plants and oil & gas facilities, businesses need engineering-grade pipeline system design and execution. A professional turnkey piping contracting company delivers complete solutions – from concept and fabrication to commissioning and long-term maintenance – ensuring operational efficiency and regulatory compliance.

Luthra Projects specializes in industrial piping contractors services that cover nitrogen vacuum inert gas piping solutions, fire prevention piping solutions, IBR boiler piping solutions, and orbital welding piping solutions. With in-house design teams and certified welders, the company supports complex projects that require precision, hygiene, and safety.

Modern industries prefer modular piping systems and prefabricated skids to reduce installation time and shutdown periods. Combined with stainless steel piping installation and carbon steel pipeline installation, turnkey delivery ensures seamless integration with existing plants.

As one of the trusted engineering piping contractors in India, Luthra Projects focuses on quality, compliance, and on-time execution across diverse sectors.

Comprehensive Pipeline System Design and Engineering

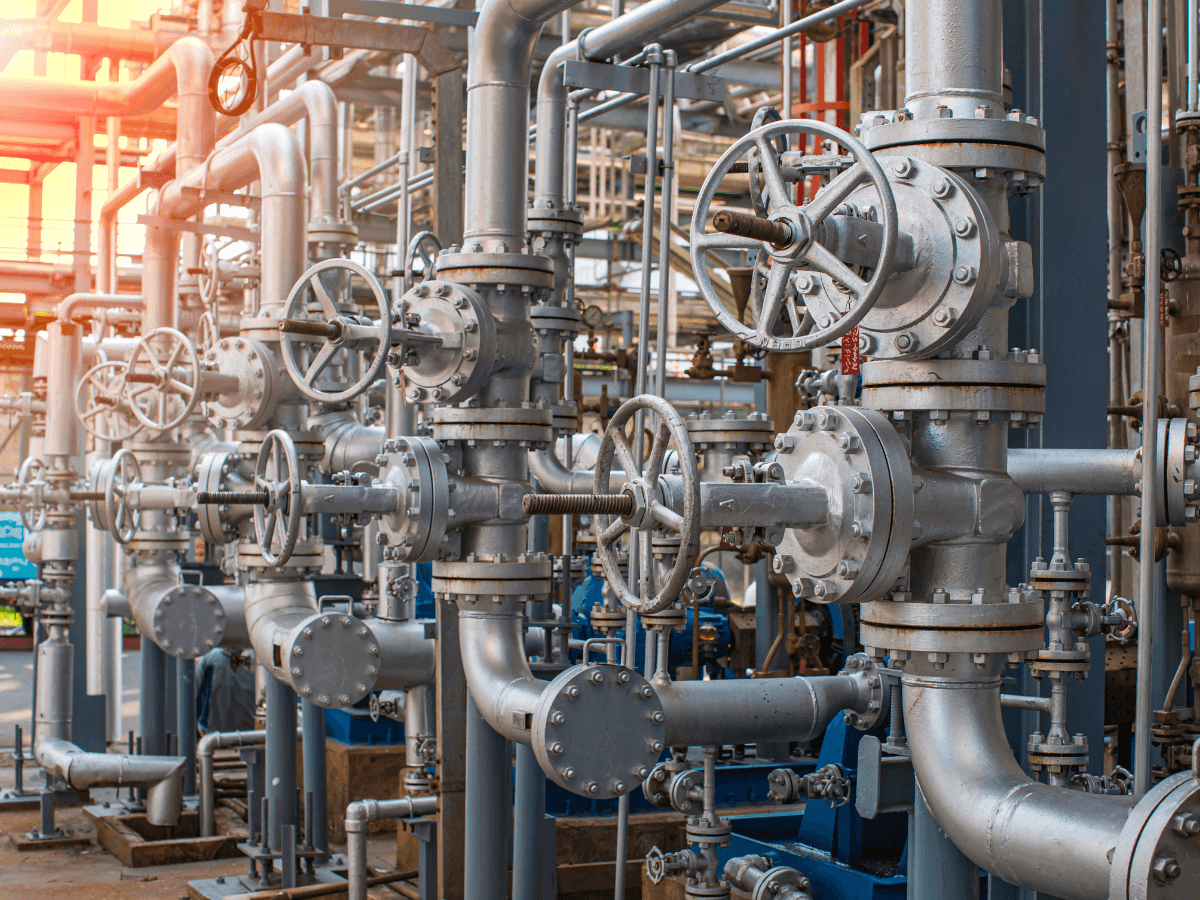

Effective industrial pipeline installation begins with accurate pipeline system design. Load calculations, pressure ratings, material compatibility, corrosion allowances, and future expansion planning are critical factors in ensuring long-term reliability.

Engineering piping contractors use advanced 3D modeling and stress analysis to design layouts for high-pressure steam lines, pharmaceutical piping solutions, and utility networks such as nitrogen vacuum inert gas piping solutions. This approach minimizes clashes, optimizes routing, and ensures compliance with ASME, IBR, and international standards.

Fire prevention piping solutions are engineered with hydraulic calculations, looped networks, and redundancy to maintain safety in high-risk industrial environments. Similarly, IBR boiler piping solutions demand precise alignment, certified materials, and inspection-ready fabrication.

Through detailed design and project consultancy, piping project consultants ensure every system performs efficiently from day one.

Turnkey Industrial Piping Installation & Fabrication

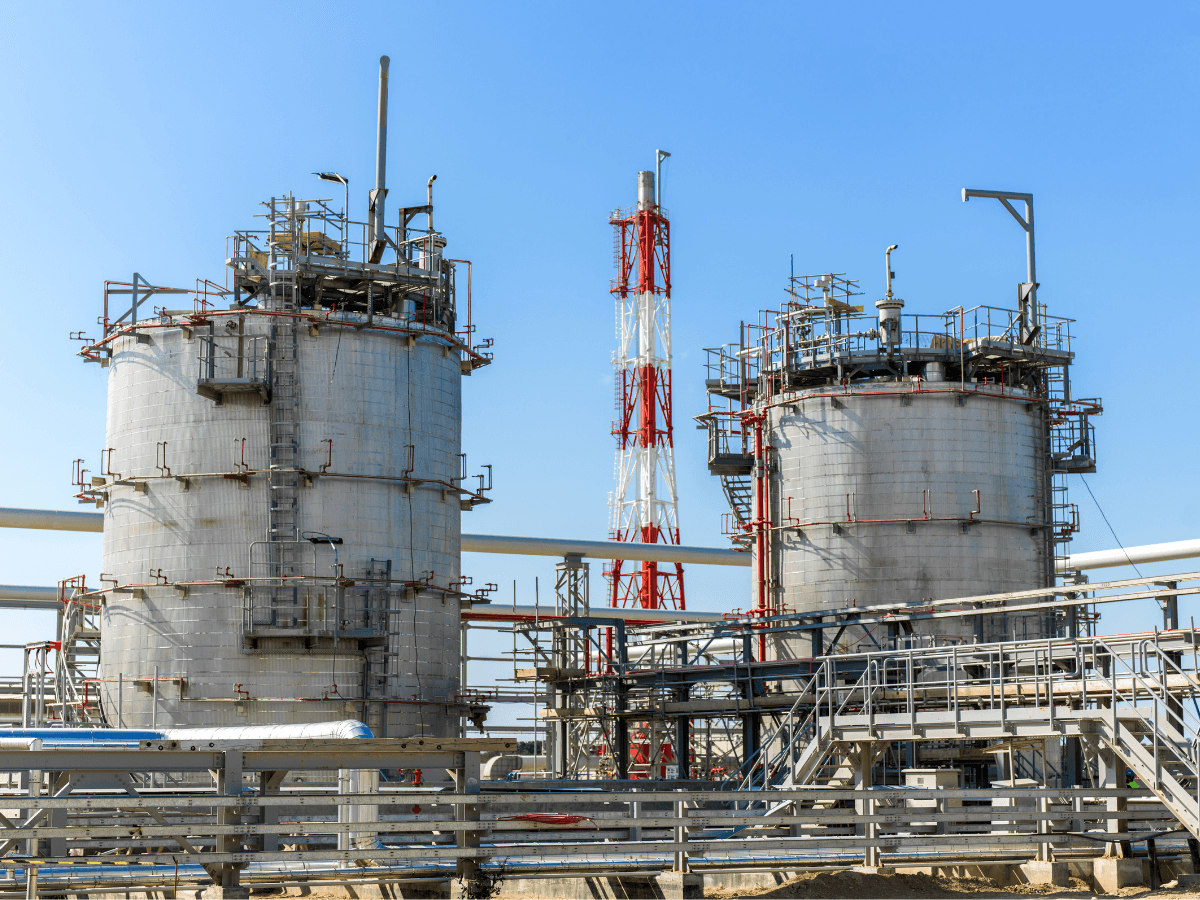

Turnkey industrial piping solutions cover procurement, fabrication, installation, testing, and commissioning under one contract. This model eliminates coordination issues between multiple vendors and improves accountability.

Stainless steel piping installation is widely used in pharmaceutical, food, and chemical industries due to corrosion resistance and hygienic properties. Carbon steel pipeline installation, on the other hand, is preferred for high-pressure steam, oil, and water transmission due to strength and cost efficiency.

Orbital welding piping solutions ensure consistent, high-quality welds, especially for cleanroom and high-purity applications. Automated welding enhances joint integrity, reduces human error, and meets stringent inspection standards.

Modular piping systems are fabricated off-site, allowing rapid on-site assembly, reduced labor hours, and minimal disruption to plant operations.

Specialized Industrial Piping Applications

Different industries require customized piping systems based on process requirements and safety norms. Pharmaceutical piping solutions demand smooth internal finishes, hygienic welds, and contamination-free installation.

Nitrogen vacuum inert gas piping solutions are essential for chemical plants, electronics manufacturing, and controlled-atmosphere facilities, ensuring process stability and safety. These systems require leak-proof joints, proper slope design, and pressure-tested networks.

Fire prevention piping solutions protect critical assets and human life through sprinkler systems, hydrant lines, and foam-based fire suppression networks.

IBR boiler piping solutions are designed for high-temperature and high-pressure steam lines, complying strictly with Indian Boiler Regulations for material traceability, welding procedures, and inspection protocols.

After-Sales Piping Maintenance & Project Consultancy

Long-term performance depends not only on installation but also on professional after-sales piping maintenance. Preventive inspections, leak detection, corrosion monitoring, and periodic pressure testing ensure uninterrupted plant operations.

Piping project consultants assist in capacity expansion, retrofitting, and system upgrades, helping industries align with changing production demands and safety regulations. Engineering piping contractors also provide shutdown planning, replacement of aging pipelines, and optimization of utility distribution systems.

With a complete lifecycle approach, turnkey piping contracting companies deliver sustainable, cost-effective solutions that enhance plant reliability and safety.

Why Choose a Turnkey Piping Contracting Company in India?

Working with a single-source industrial piping contractor ensures faster execution, better coordination, and strict quality control. From design and modular fabrication to orbital welding and commissioning, all activities are managed under unified project leadership.

Turnkey industrial piping solutions reduce risk, optimize budgets, and ensure compliance with international standards. This integrated approach is ideal for large-scale industrial pipeline installation projects across power, pharma, chemical, oil & gas, and manufacturing sectors.

FAQs – Industrial Piping Solutions

Q1. What are turnkey industrial piping solutions?

Turnkey solutions include complete pipeline system design, fabrication, installation, testing, commissioning, and maintenance under a single contract.

Q2. Why is orbital welding important for pharmaceutical piping solutions?

Orbital welding ensures uniform, contamination-free welds, meeting strict hygiene and quality standards.

Q3. What materials are commonly used in industrial piping installation?

Stainless steel piping installation is used for corrosion resistance and hygiene, while carbon steel pipeline installation is preferred for strength and high-pressure applications.

Q4. What are nitrogen vacuum inert gas piping solutions used for?

They are used in chemical processing, electronics, and controlled environments to prevent oxidation and maintain product integrity.

Q5. Do turnkey piping contractors provide after-sales maintenance?

Yes, professional contractors offer after-sales piping maintenance, inspections, and system upgrades for long-term reliability.

Leave a comment