Turnkey Solutions for Nitrogen, Vacuum & Inert Gas Piping Systems in India

At Luthra Projects, we deliver end-to-end piping solutions for Nitrogen, Vacuum, and other Inert Gas systems, engineered to meet the critical demands of industrial and process-specific applications. Our custom-designed piping infrastructure ensures leak-proof performance, precision gas distribution, and compliance with stringent purity and safety standards required by industries such as pharmaceuticals, electronics, food & beverage, cleanrooms, R&D facilities, and manufacturing plants.

We manage the complete project lifecycle—from system design and flow calculation to material supply, installation, pressure testing, and final commissioning—ensuring each project meets the highest standards of efficiency, durability, and reliability.

Our Complete Scope of Work

System Design & Flow Calculation

- Tailored designs based on gas consumption rates, pressure requirements, piping distances, and point-of-use demands.

- Incorporation of energy efficiency measures and flow optimization techniques for reduced operational costs.

- CAD-based piping layout drawings for accurate planning and execution.

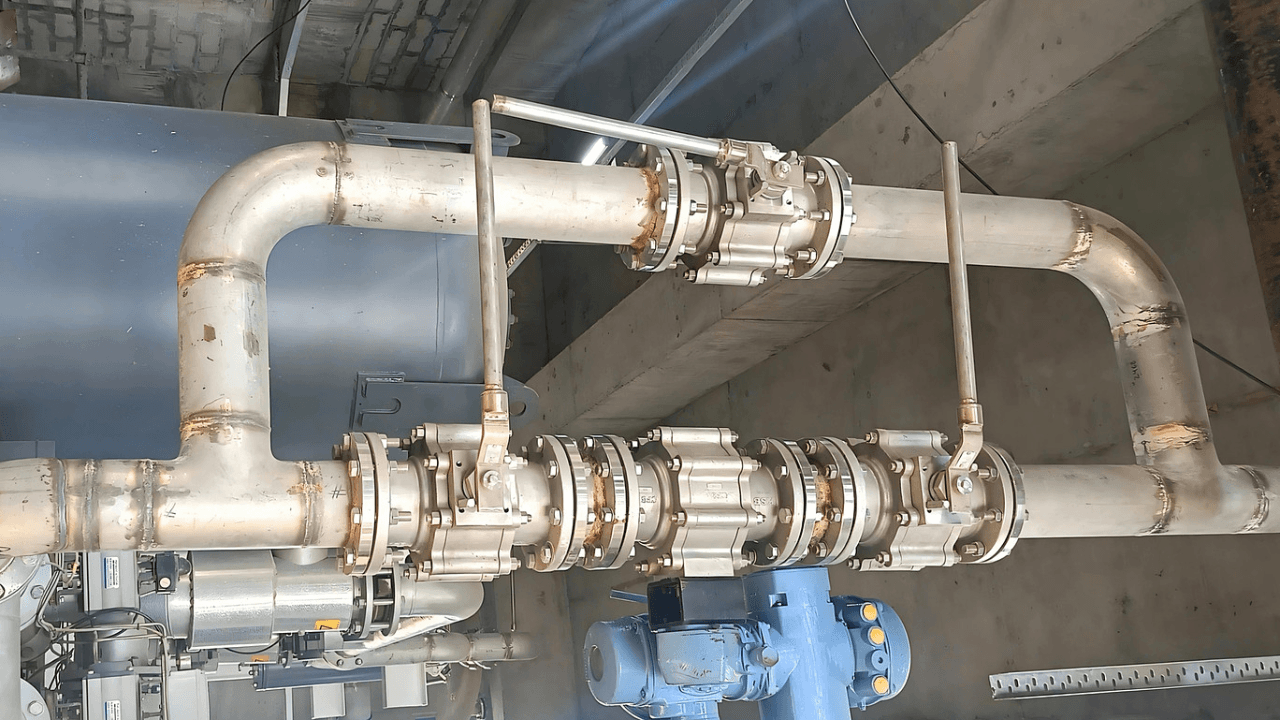

Supply & Installation

- Procurement and installation of high-grade piping, valves, manifolds, regulators, vacuum pumps, gauges, and fittings.

- Expertise in both pressurized and negative-pressure systems for various industrial setups.

- On-site installation with strict adherence to international safety and quality standards.

Erection & Commissioning

- Full mechanical erection of piping networks.

- Helium and nitrogen leak testing, hydrostatic pressure trials, and system validation.

- Final commissioning to ensure stable, efficient, and safe gas delivery.

Interfacing with Process Equipment & Gas Banks

- Precision routing to connect gas cylinders, vacuum chambers, CNC machinery, cleanroom utilities, and laboratory setups.

- Integration with safety devices, alarms, and monitoring systems for risk-free operations.

Industrial Gases & Applications We Serve

- Nitrogen Gas Systems – For inerting, purging, blanketing, food packaging, and pneumatic operations.

- Vacuum Systems – For CNC machining, semiconductor manufacturing, laboratory research, and industrial packaging lines.

- Other Inert Gases – Argon, CO₂, and Helium for welding, metal processing, heat treatment, and precision laboratory applications.

Piping Materials & Options

- Stainless Steel (SS 304 / SS 316) – Seamless tubes for high-purity, corrosion-resistant gas systems.

- Copper Tubing – Brazed joints for secure, hygienic, and efficient gas transport.

- Aluminum Modular Piping Systems – Lightweight, durable, and corrosion-resistant infrastructure.

- High-Purity Orbital Welding – Precision welding for cleanroom-grade gas lines.

- Vacuum-Rated Valves & Regulators – Optimized for minimal leakage and consistent flow performance.

Why Choose Luthra Projects for Industrial Gas Piping?

- Proven expertise in turnkey gas piping projects across multiple sectors.

- Custom-engineered designs for maximum efficiency and safety.

- Compliance with BIS, ASME, and international piping standards.

- On-time project execution with minimal operational downtime.

- Dedicated quality control and safety assurance protocols.

Luthra Projects ensures that every Nitrogen, Vacuum, and Inert Gas piping system is reliable, safe, and built to last, meeting the demanding needs of industries where purity, precision, and performance are non-negotiable.

Contact us today to discuss your industrial gas piping requirements and get a customized, cost-effective, and high-performance solution.

FAQ – Nitrogen, Vacuum & Inert Gas Piping Solutions

What are turnkey nitrogen, vacuum, and inert gas piping systems?

Turnkey systems are complete, custom-designed piping solutions that include system design, material supply, installation, and commissioning. These systems are engineered for reliable and efficient gas distribution in industrial environments, ensuring leak-proof, pressure-tested performance.

What industries can benefit from nitrogen, vacuum, and inert gas systems?

Industries such as electronics, pharmaceuticals, food & beverage, semiconductor manufacturing, and metal processing benefit from these systems for applications like inerting, purging, blanketing, and welding.

How do you ensure the safety and purity of gas systems?

Our systems are designed to meet the highest safety and purity standards, including helium/nitrogen leak testing, pressure trials, and orbital welding for clean applications, ensuring zero leakage and consistent gas flow.

What gases are included in your piping solutions?

We handle nitrogen, vacuum, and other inert gases such as argon, CO₂, and helium. These gases are used in various applications like welding, heat treatment, metal processing, and cleanroom environments.

What materials are used for the gas piping systems?

We use Stainless Steel (SS 304/316), copper tubing, aluminum modular piping, and high-purity orbital welding for optimal performance, ensuring durability, corrosion resistance, and precision in gas handling systems.