End-to-End Turnkey Solutions for Fire Prevention Piping Systems

Luthra Projects delivers end-to-end turnkey fire prevention piping solutions engineered to meet stringent fire safety regulations and international industrial standards. We provide complete solutions — from custom fire safety system design to installation, testing, and final commissioning — ensuring your facility is equipped with reliable, performance-tested fire protection infrastructure.

Our expertise in industrial environments and seamless integration with existing utility systems ensures long-term safety, operational efficiency, and regulatory compliance across a wide range of industries.

Why Choose Luthra Projects for Fire Prevention Piping?

- Comprehensive Turnkey Execution – From concept to commissioning under one roof

- Strict Compliance – Designed to meet IS, NFPA, and UL/FM fire safety standards

- Tailored Designs – Based on hazard risk, plant layout, and industry requirements

- Proven Reliability – Tested and validated systems for long-term protection

- Multi-Industry Expertise – Serving manufacturing, pharma, food & beverage, electronics, and more

Our Complete Scope of Work

Fire Safety System Design & Layout

We develop custom-designed fire safety piping layouts based on:

- Detailed risk assessments and hazard classification

- Facility blueprints and plant layouts

- Applicable national and international fire safety codes

- Future scalability and maintenance considerations

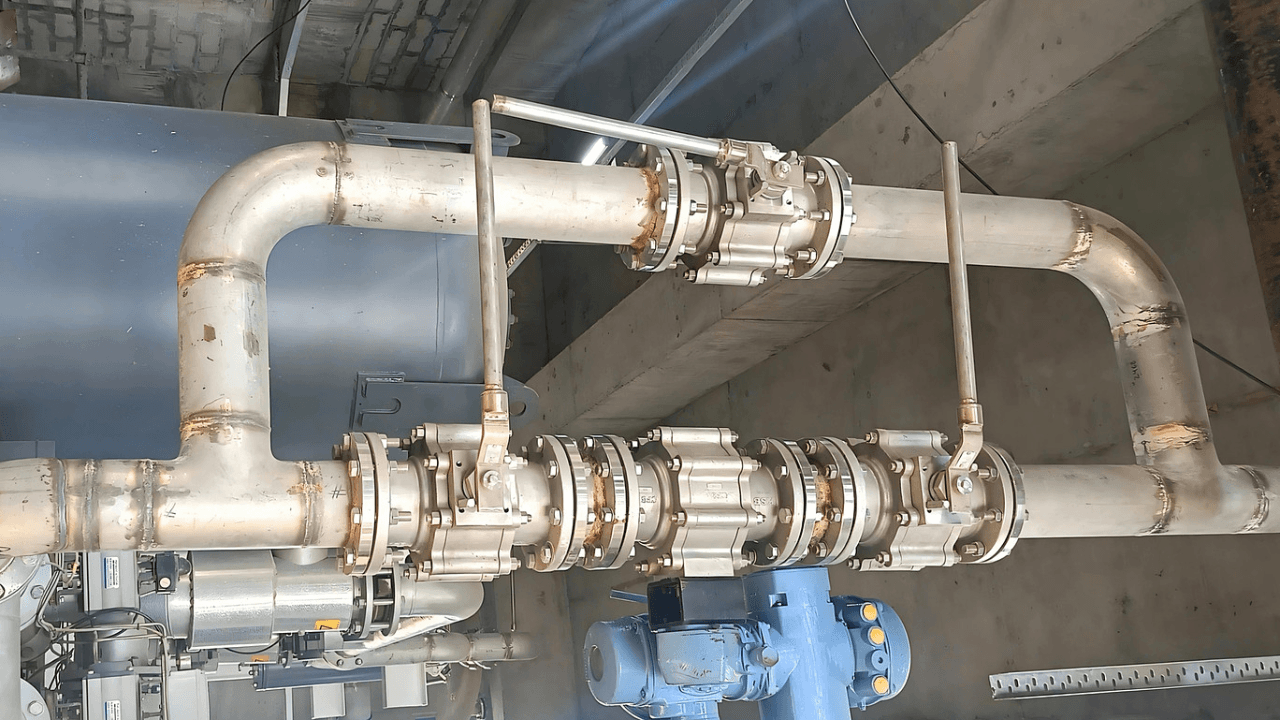

Supply & Installation

We source and install high-quality, certified fire prevention equipment:

- Pipes: MS/CS (welded/seamless) with red oxide or epoxy coating, GI pipes, SS pipes

- Valves, fittings, and accessories – UL/FM-approved for global compliance

- Fire hydrants, hose reels, sprinklers, nozzles, and monitors

- Pumps and controllers designed to maintain adequate water pressure

- Accessories for optimum flow control and system durability

Erection & Commissioning

Our process ensures safe, tested, and compliant installation:

- Full mechanical erection of piping networks

- Pressure testing and flushing for system integrity

- Calibration of pumps and flow control devices

- Certified commissioning in line with IS/NFPA standards

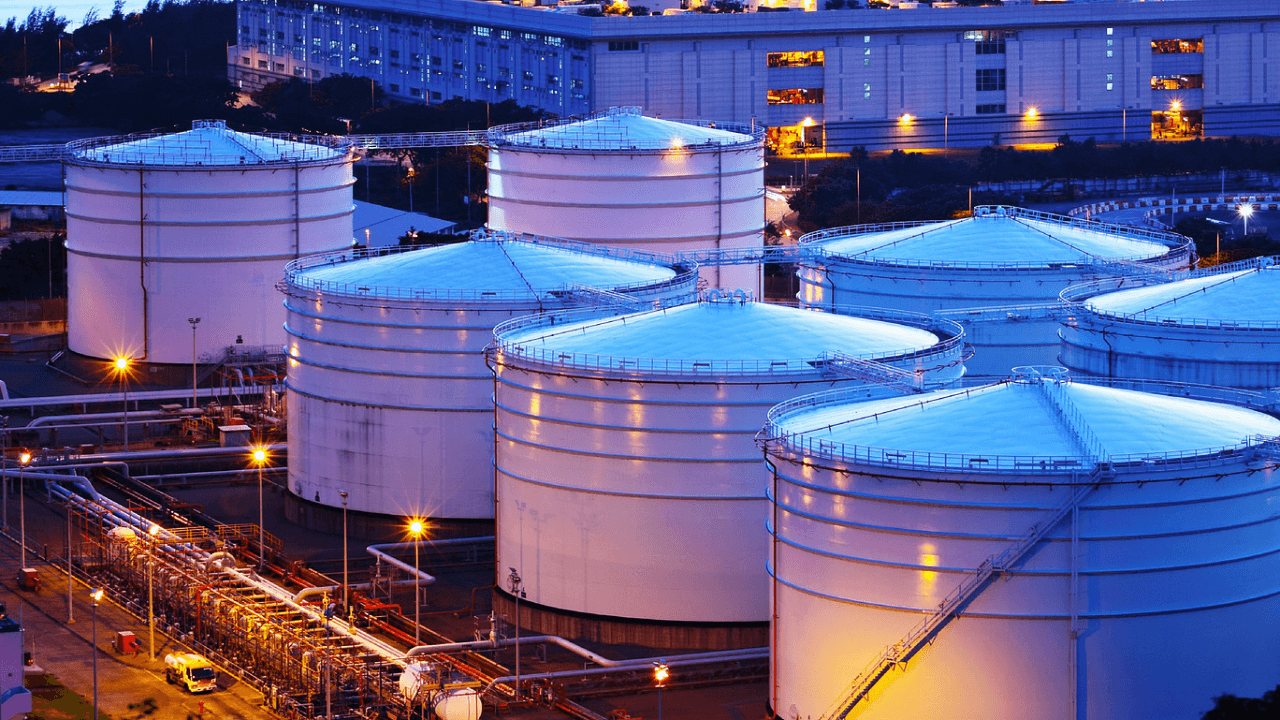

Integration with Existing Infrastructure

We ensure minimal operational disruption by:

- Routing fire piping through strategic paths in existing plant layouts

- Integrating with utility systems, storage tanks, and water supply lines

- Coordinating with other mechanical and electrical systems

Piping Materials & Options We Offer

Durable & Safe Pipe Options

- MS/CS Pipes (Welded/Seamless) – Coated with red oxide or epoxy for corrosion resistance

- Galvanized Iron (GI) Pipes – Added protection for outdoor and corrosive environments

- Stainless Steel (SS) – For high-performance, hygiene-sensitive areas

Fire Safety-Approved Components

- UL/FM-approved valves, fittings, and accessories

- Fire-rated supports, brackets, and expansion joints for structural safety

Industries We Serve

Our fire prevention piping systems are trusted across sectors such as:

- Manufacturing Units

- Pharmaceutical Plants

- Food & Beverage Processing Units

- Electronics & Semiconductor Facilities

- Automotive & Engineering Plants

- Warehouses & Logistic Centers

Advantages of Our Turnkey Fire Prevention Solutions

- Guaranteed compliance with IS, NFPA, and global standards

- Cost-effective yet high-performance fire safety systems

- Reduced project timelines through in-house expertise

- Proven reliability and operational safety

- Tailored designs for unique facility needs

Partner with Luthra Projects for Reliable Fire Safety

At Luthra Projects, we prioritize safety, compliance, and performance in every fire prevention piping system we deliver. Whether you need a new fire safety installation or integration into existing infrastructure, our turnkey approach ensures peace of mind and long-term protection for your facility.

FAQ – Fire Prevention Piping Solutions

What are turnkey fire prevention piping solutions?

Turnkey fire prevention piping solutions involve comprehensive services from system design to installation and commissioning. Luthra Projects custom-engineers each system to ensure it meets fire safety regulations and industry standards, providing reliable and efficient fire protection for your facility.

How do you design fire safety piping systems?

Our fire safety piping systems are custom-designed based on risk assessments, hazard classifications, and plant layouts. We ensure the design meets all necessary fire safety codes and is tailored to the unique needs of your facility.

What materials are used in fire prevention piping systems?

We use MS/CS pipes (welded or seamless) with red oxide or epoxy coating, GI pipes, and stainless steel (SS) for select applications. We also provide UL/FM-approved valves, fittings, and fire-rated supports for maximum safety.

What industries do your fire prevention piping solutions serve?

Our solutions are ideal for industries such as manufacturing, pharmaceuticals, food & beverage, electronics, and more. We design systems that comply with fire safety regulations in various environments, including high-risk and controlled areas.

How do you ensure the reliability of the installed fire safety systems?

We conduct pressure testing, flushing, and system validation to ensure the system operates efficiently. Our systems are fully commissioned with certified safety protocols, offering long-term reliability and compliance with fire safety standards.